Diamond Blade for Surfaces-Floor / Road Saws Range: SIMAPremium

Materials: Hard Concrete. Diameter: 20"/500mm.

Diamond Blade for Surfaces-Floor / Road Saws Range: SIMAPremium

Materials: Hard Concrete. Diameter: 20"/500mm.

Diamond Blade for Surfaces-Floor / Road Saws Range: SIMAPremium

Materials: Hard Concrete. Diameter: 18"/450mm.

Diamond Blade for Dry Cutting Range: SIMAPlus Materials:All Materials-Silent. Diameter: 9,0"/230mm. Turbo Segmented Laser.

Diamond Blade for Dry Cutting Range: SIMAPlus

Materials: Concrete. Diameter:9,0"/230mm. Turbo Rim.

Diamond Blade for Dry Cutting Range: SIMAPlus

Materials: Granite. Diameter: 9"/230mm. Laser welded segment.

Diamond Blade for Dry Cutting Range: SIMAPlus

Materials: Abrasive Materials. Diameter: 9,0"/230mm. Laser welded segment.

Diamond Blade for Dry CuttingRange:SIMAPlus

Materials:Ceramics and Glazed Tiles Brown.Diameter:8"/230mm.Continuous Rim.

Diamond Blade for Dry Cutting Range: SIMAPlus Materials: Concrete. Diameter:10"/250mm. Turbo Rim.

Blade TCT WIDIA para Dry Cut Gama: SIMAPlus

Materials: Structural Insulated Panels -Steel- Diameter: 350 mm

Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 250 mm Laser welded segment.

Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 350 mm Laser welded segment.

Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 400 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 450 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 500 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 600 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 650 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 700 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 900 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Roof Tiless, Brick, Clinker, Concrete. Diameter: 1000 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Marble, Sandstone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Marble, Sandstone. Diameter: 350 mm Laser welded segment.

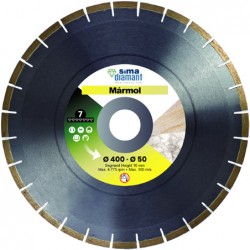

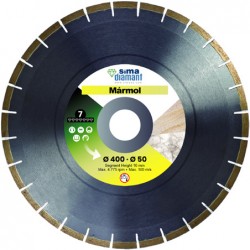

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Marble, Sandstone. Diameter: 400 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Marble, Sandstone. Diameter: 500 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Granite, Silestone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Granite, Silestone. Diameter: 350 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Granite, Silestone. Diameter: 400 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Granite, Silestone. Diameter: 500 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 180 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 200 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 250 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 350 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Marble, Dekton. Diameter: 200 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Marble, Dekton. Diameter: 230 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Marble, Dekton. Diameter: 250 mm Laser welded segment.

A diamond blade consists of a core or body of high precision steel with a mix of metal powder, diamond segments, and a resin bond that keeps it all together. The sizes and thus the hardness of the diamonds are designed with different concentrations, depending on the kind of blade, or in other words, depending on the material that it will cut. To finish the product, we put it through a specific thermic process that makes it highly resistant.

As diamond blades professionals, SIMA’s manufacturers take into account every variable when recommending a specific blade to suit the needs of every specific customer and his needs.

In general, if you are going to cut hard materials, we recommend using a blade made of softer metal bonds and bigger diamond particles. On the other hand, when you are working with highly abrasive or soft materials, you should use more resistant metal pieces and less diamond segments. Nevertheless, check your options with our technicians to get a professional approach on the matter for your specific case.

Remember that even two pieces made of the same material will slightly differ in their compositions depending, for example, on their origin, and affecting its abrasiveness and performance.

So, what do you need to take into account when choosing a masonry saw blade?

-The material you will be working with

-The saw or machine you will be using

-The blade diameter

SIMA Diamant offers two different diamond blades series: the PLUS and the PREMIUM. The main difference is that the PREMIUM one has a higher-performance segment.

If you need to cut harder materials like granite, bricks or stone and you do not need a super accurate cut, we recommend you choose a segmented disc because it will work faster and save you a lot of time and trouble. If you are looking for a more precise cut or you will be working with materials prone to chipping, we recommend a turbo disc.

And last but not least, if you are working with ceramic materials, our professionals recommend getting a rim masonry diamond blade. It offers high cutting accuracy and neat cut.

SIMA, the most professional tile saw blades and diamond masonry saw blades across Europe.

As leaders in the masonry saw blades industry across Europe and specifically in the UK, SIMA Diamant offers a great variety of materials and machines to create professional diamond masonry blades and core bits. The meticulous process our technicians follow to manufacture every masonry diamond cutting blade has been thought to include high-frequency welding, as well as gas welding and laser welding.

SIMA’s R&D department is constantly working on new developments to design an improved diamond masonry saw blade and other accessories. Our professional staff works in a metrology lab equipped with high-quality scientific tools. By investing in our laboratories and technicians, SIMA provides only the finest diamond masonry blades.

Find the best diamond tile blade or diamond masonry blade online for your specific needs and if you are shopping in the UK, take advantage of our free shipping and returns.